Next: Light collection

Up: Design and Construction

Previous: BGO and radiation hardness

Contents

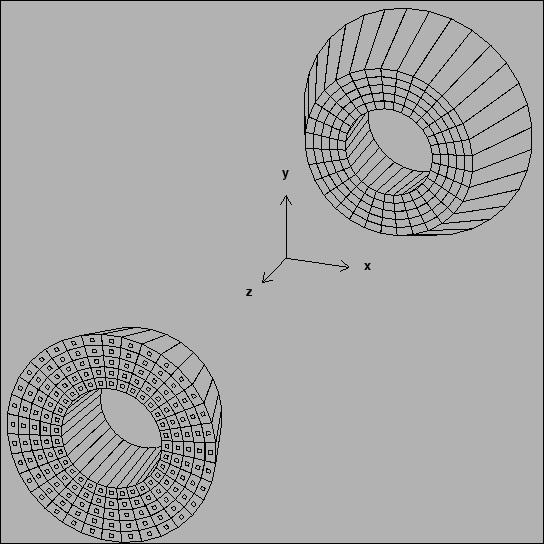

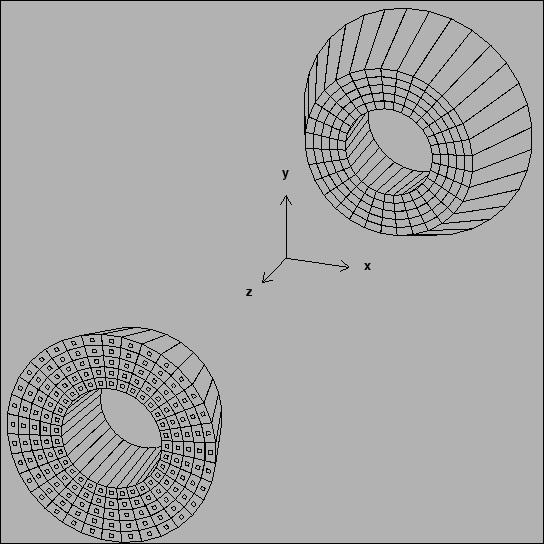

The finer lateral segmentation can provide the better position

resolution. The segmentation, however, is limited by front-end

electronics. The detector is segmented into 32 in  and 5 in

and 5 in

for both the forward and backward cones. A three dimensional

view of the crystal arrangement is shown in

Fig.

for both the forward and backward cones. A three dimensional

view of the crystal arrangement is shown in

Fig. ![[*]](./icons/crossref.png) .

.

Figure:

An isometric view of the BGO crystals of the forward and

backward EFC detectors.

|

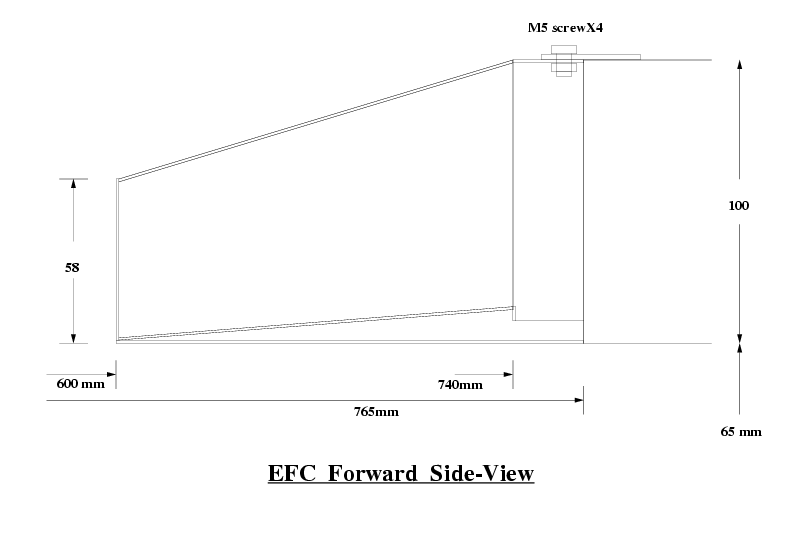

The schematic side view of the forward EFC is shown in

Fig. ![[*]](./icons/crossref.png) . The distance between the front surface of

the detector and the interaction point is 60 and 43.5 cm in the

forward and backward EFCs, respectively. The inner bore radius of the

detector is 6.5 cm.

. The distance between the front surface of

the detector and the interaction point is 60 and 43.5 cm in the

forward and backward EFCs, respectively. The inner bore radius of the

detector is 6.5 cm.

Figure:

Side view of the mounting of forward EFC.

|

The BGO crystals are housed in a bucket-shape container made of 1

mm-thick stainless steel, the inner bore of which is the beam pipe.

The container is attached to the front surface of the compensation

solenoids. Since the space allocated for EFC is limited, the radiation

lengths of the forward and backward crystals are 12 and 11,

respectively. Front-end circuits for photodiodes and preamps as well

as miscellaneous instruments are installed in the space between the

magnet surface and the backend of the BGO crystals which is 2.7 and

2.0 cm for the forward and backward EFC detectors, respectively.

Next: Light collection

Up: Design and Construction

Previous: BGO and radiation hardness

Contents

Samo Stanic

2001-06-02