Next: Gas

Up: Design and Construction of

Previous: Design and Construction of

Contents

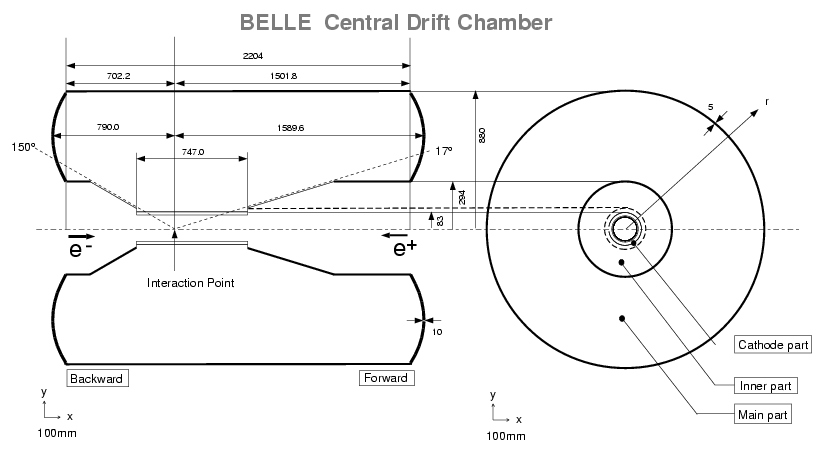

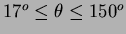

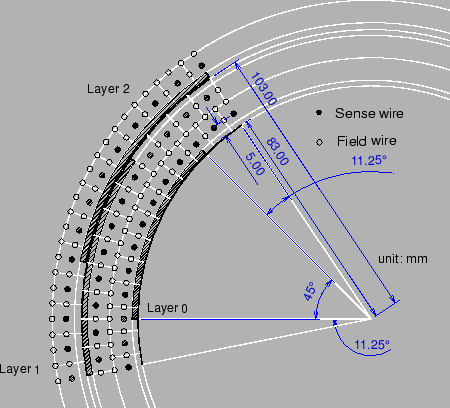

The structure of CDC is shown in Fig.

![[*]](./icons/crossref.png) . It is asymmetric in the

. It is asymmetric in the  direction in

order to provide an angular coverage of

direction in

order to provide an angular coverage of

.

The longest wires are 2400 mm long. The inner radius is extended down

to 103.5 mm without any walls in order to obtain good tracking

efficiency for low-

.

The longest wires are 2400 mm long. The inner radius is extended down

to 103.5 mm without any walls in order to obtain good tracking

efficiency for low- tracks by minimizing the material

thickness. The outer radius is 874 mm. The forward and backward

small-

tracks by minimizing the material

thickness. The outer radius is 874 mm. The forward and backward

small- regions have conical shapes in order to clear the

accelerator components while maximizing the acceptance.

regions have conical shapes in order to clear the

accelerator components while maximizing the acceptance.

The chamber has 50 cylindrical layers, each containing between three

and six either axial or small-angle-stereo layers, and three cathode

strip layers.

Table ![[*]](./icons/crossref.png) gives the detailed parameters of the wire

configuration. CDC has a total of 8400 drift cells. We chose three

layers each for the two innermost stereo super-layers and four layers

each for the three outer stereo super-layers in order to provide a

highly-efficient fast

gives the detailed parameters of the wire

configuration. CDC has a total of 8400 drift cells. We chose three

layers each for the two innermost stereo super-layers and four layers

each for the three outer stereo super-layers in order to provide a

highly-efficient fast  -trigger combined with the cathode strips. We

determined the stereo angles in each stereo super-layer by maximizing

the

-trigger combined with the cathode strips. We

determined the stereo angles in each stereo super-layer by maximizing

the  -measurement capability while keeping the gain variations along

the wire below 10 %.

-measurement capability while keeping the gain variations along

the wire below 10 %.

Figure:

Overview of the CDC structure. The lengths in the figure are

in units of mm.

|

Table:

Configurations of the CDC sense wires and cathode strips.

| Superlayer |

No. of |

Signal channels |

Radius |

Stereo angle (mrad) |

| type and No. |

layers |

per layer |

(mm) |

and strip pitch (mm) |

| Cathode |

1 |

64 (z)  8 ( 8 ( ) ) |

83.0 |

(8.2) |

| Axial 1 |

2 |

64 |

88.0  98.0 98.0 |

0. |

| Cathode |

1 |

80 (z)  8 ( 8 ( ) ) |

103.0 |

(8.2) |

| Cathode |

1 |

80 (z)  8 ( 8 ( ) ) |

103.5 |

(8.2) |

| Axial 1 |

4 |

64 |

108.5  159.5 159.5 |

0. |

| Stereo 2 |

3 |

80 |

178.5  209.5 209.5 |

71.46  73.75 73.75 |

| Axial 3 |

6 |

96 |

224.5  304.0 304.0 |

0. |

| Stereo 4 |

3 |

128 |

322.5  353.5 353.5 |

-42.28  -45.80 -45.80 |

| Axial 5 |

5 |

144 |

368.5  431.5 431.5 |

0. |

| Stereo 6 |

4 |

160 |

450.5  497.5 497.5 |

45.11  49.36 49.36 |

| Axial 7 |

5 |

192 |

512.5  575.5 575.5 |

0. |

| Stereo 8 |

4 |

208 |

594.5  641.5 641.5 |

-52.68  -57.01 -57.01 |

| Axial 9 |

5 |

240 |

656.5  719.5 719.5 |

0. |

| Stereo 10 |

4 |

256 |

738.5  785.5 785.5 |

62.10  67.09 67.09 |

| Axial 11 |

5 |

288 |

800.5  863.0 863.0 |

0. |

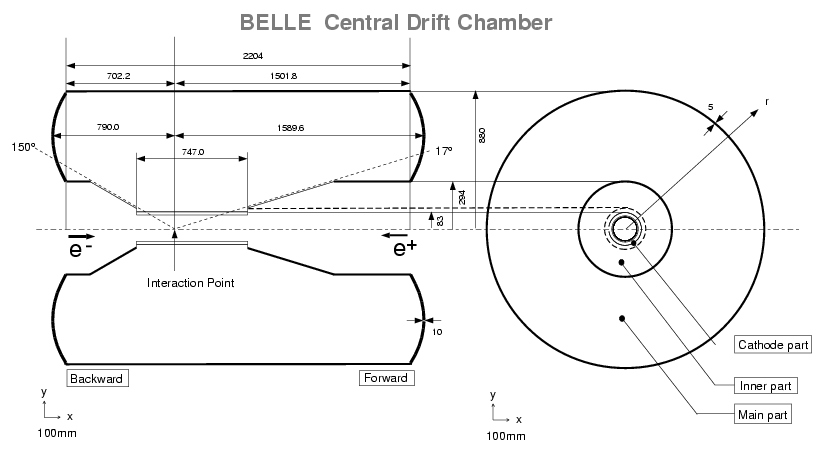

The individual drift cells are nearly square and, except for the inner

three layers, have a maximum drift distance between 8 and 10 mm and a

radial thickness that ranges from 15.5 to 17 mm. The drift cells in

the inner layers are smaller than the others and their signals are

read out by cathode strips on the cylinder walls. These cell

dimensions were optimized based on the results of beam test

measurements [32].

Fig. ![[*]](./icons/crossref.png) shows the cell arrangement in which the

neighboring radial layers in a superlayer are staggered in

shows the cell arrangement in which the

neighboring radial layers in a superlayer are staggered in  by a

half cell to resolve left-right ambiguities. The sense wires are gold

plated tungsten wires of 30

by a

half cell to resolve left-right ambiguities. The sense wires are gold

plated tungsten wires of 30  m in diameter to maximize the drift

electric field. The field wires of unplated aluminum of 126

m in diameter to maximize the drift

electric field. The field wires of unplated aluminum of 126  m in

diameter are arranged to produce high electric fields up to the edge

of the cell and also to simplify the drift time-to-distance relation.

The aluminum field wires are used to reduce the material of the

chamber. The electric field strength at the surface of the aluminum

field wires is always less than 20 kV/cm, a necessary condition for

avoiding radiation damage [33].

m in

diameter are arranged to produce high electric fields up to the edge

of the cell and also to simplify the drift time-to-distance relation.

The aluminum field wires are used to reduce the material of the

chamber. The electric field strength at the surface of the aluminum

field wires is always less than 20 kV/cm, a necessary condition for

avoiding radiation damage [33].

Figure:

Cell structure of CDC.

|

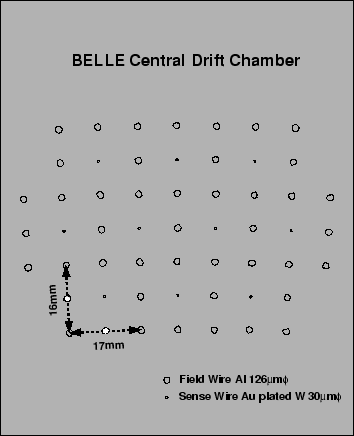

Three  -coordinate measurements at the inner-most radii are provided

by cathode strips as shown in

Fig.

-coordinate measurements at the inner-most radii are provided

by cathode strips as shown in

Fig. ![[*]](./icons/crossref.png) [34]. They were glued on

the inner cylinder surface of the chamber and on both sides of a 400

[34]. They were glued on

the inner cylinder surface of the chamber and on both sides of a 400

m thick CFRP cylinder located between the second and third anode

layers. In order to maintain the mechanical strength and accuracy,

aluminum guard rings were attached on the both ends with electrically

conducting glue. The deviation from a perfect cylindrical shape is

less than 100

m thick CFRP cylinder located between the second and third anode

layers. In order to maintain the mechanical strength and accuracy,

aluminum guard rings were attached on the both ends with electrically

conducting glue. The deviation from a perfect cylindrical shape is

less than 100  m in radius. The cathode strips are divided into

eight segments in the

m in radius. The cathode strips are divided into

eight segments in the  direction and have an 8.2 mm pitch in the

direction and have an 8.2 mm pitch in the

direction. The strip width is 7.4 mm. The total number of cathode

channels is 1,792. The deterioration of the momentum resolution due

to multiple scattering in the cathode materials is minimized.

direction. The strip width is 7.4 mm. The total number of cathode

channels is 1,792. The deterioration of the momentum resolution due

to multiple scattering in the cathode materials is minimized.

Figure:

Cell structure and the cathode sector configuration.

|

The total wire tension of 3.5 tons is supported by the aluminum

end-plates and the CFRP cylinder structures that extend between the

end-plates. Each end plate consists of three parts; the cathode,

inner and main parts as indicated in

Fig. ![[*]](./icons/crossref.png) . The cathode part of a 16 mm thick flat

plate corresponds to the three innermost anode layers and three

cathode layers. The conically-shaped inner part covers 11 anode layers

in the radial range from 103.5 to 294 mm. The end-plate thickness in

the

. The cathode part of a 16 mm thick flat

plate corresponds to the three innermost anode layers and three

cathode layers. The conically-shaped inner part covers 11 anode layers

in the radial range from 103.5 to 294 mm. The end-plate thickness in

the  direction is 11

direction is 11  18 mm for the backward side and 25

18 mm for the backward side and 25

31 mm for the forward side. The end-plate of the main part is

10 mm in thickness and has a curved profile to minimize distortions

caused by the wire tension. The three end-plate parts are connected to

each other by stainless steel bolts and gas sealed with silicone glue.

The 754.5 mm radial space between the 3rd and 50th anode layers

contains only gases and wires.

31 mm for the forward side. The end-plate of the main part is

10 mm in thickness and has a curved profile to minimize distortions

caused by the wire tension. The three end-plate parts are connected to

each other by stainless steel bolts and gas sealed with silicone glue.

The 754.5 mm radial space between the 3rd and 50th anode layers

contains only gases and wires.

The feed-through holes were drilled by a custom designed drilling

machine at the KEK machine shop. The hole position accuracy is better

than 30  m.

m.

Next: Gas

Up: Design and Construction of

Previous: Design and Construction of

Contents

Samo Stanic

2001-06-02