Next: Monitor System

Up: Silicon Vertex Detector, SVD

Previous: Trigger Timing Modules

Contents

The SVD DAQ system consists of a data manager, a run manager and an

interlock. The data manager transfers data from the FADC output FIFOs

to the central event builder and the run manager controls the DAQ

hardware. The interlock monitors running conditions and sends signals

to the run manager when an abnormal state is detected.

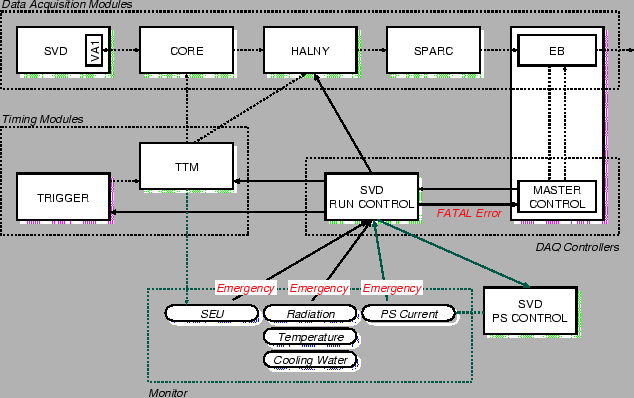

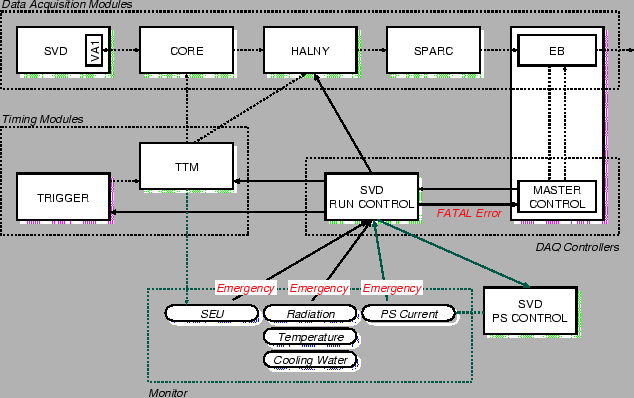

Fig. ![[*]](./icons/crossref.png) shows a block diagram of the data acquisition

and the monitoring system for SVD. The SVD back-end electronics

system comprises a TTM system in a VME crate and four FADC VME

systems. An FADC system consists of eight FADC modules and a SPARC

VME module. The VME modules (TDM, TTMs and HALNYs) are controlled by

a VME master module (i.e. a SPARC VME module) in each VME crate.

shows a block diagram of the data acquisition

and the monitoring system for SVD. The SVD back-end electronics

system comprises a TTM system in a VME crate and four FADC VME

systems. An FADC system consists of eight FADC modules and a SPARC

VME module. The VME modules (TDM, TTMs and HALNYs) are controlled by

a VME master module (i.e. a SPARC VME module) in each VME crate.

Figure:

Block diagram of the SVD DAQ system.

|

The four FADC subsystems collect and transmit data to the event

builder in parallel. SPARC VME boards resident in each of the four

FADC crates carry out this task. The SPARC VME boards poll the status

of each HALNY board in its crate and waits for a response indicating

that a digitized event is ready to be read. HALNY data is transferred

from the output FIFOs on a word-by-word basis.

The SVD run manager controls DAQ VME modules (TDM, TTMs and HALNYs).

It initiates or terminates trigger sequences, downloads firmware to

the TTMs and Halnys, and issues resets at the beginning of each run

and when requested by CDAQ. It also controls the run mode of the VA1

and CORE front-end electronics, via TTMs. Finally, it initiates

recovery procedures upon request from the interlock.

The SVD interlock system monitors running conditions of SVD. The data

integrity is checked by the consistency of the event size and

begin/end event markers. The condition of VA1s is monitored by

checking the digital outputs from the hybrids and by tracking their

power-supply currents. Temperatures of the hybrids, heat-sinks and

end-rings, and water circulation are monitored to make sure that the

cooling system is in working order. The beam abort signal from the

radiation monitor described below is also fed into the interlock.

When the system senses a fault condition on one of its inputs, it

shuts down the power supplies for the front-end electronics and sends

an abort signal to the run manager.

Next: Monitor System

Up: Silicon Vertex Detector, SVD

Previous: Trigger Timing Modules

Contents

Samo Stanic

2001-06-02