Next: End-cap modules

Up: Design and Construction

Previous: Glass Resistive Plate Counters

Contents

There are minor differences between the barrel and the end-cap modules.

The barrel resistive plate counters which were constructed in the

United States consist of two parallel sheets of 2.4 mm-thick

commercially available float glass, the content of which is 73 %

silicon dioxide, 14 % sodium oxide, 9 % calcium oxide, and 4 %

trace elements. The bulk resistivity of the glass is -

cm at room temperature. The plates are separated

by 1.9 mm thick extruded noryl spacers epoxied to both plates using 3M

2216 epoxi.

Fig.

cm at room temperature. The plates are separated

by 1.9 mm thick extruded noryl spacers epoxied to both plates using 3M

2216 epoxi.

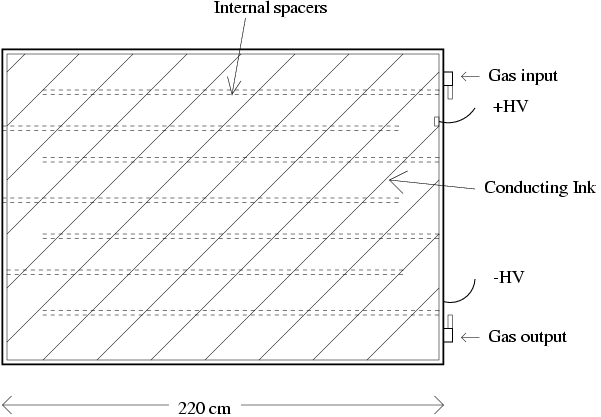

Fig. ![[*]](./icons/crossref.png) shows a barrel RPC with the spacers placed

every 10 cm so that they channel the gas flow through the RPC to

provide uniform gas composition throughout the active volume. A

T-shaped noryl spacer was epoxied around the perimeter forming a gas

tight unit. The spacers have the cross sections shown in

Fig.

shows a barrel RPC with the spacers placed

every 10 cm so that they channel the gas flow through the RPC to

provide uniform gas composition throughout the active volume. A

T-shaped noryl spacer was epoxied around the perimeter forming a gas

tight unit. The spacers have the cross sections shown in

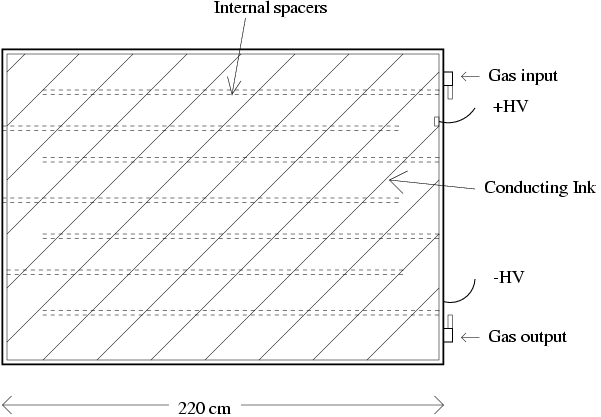

Fig. ![[*]](./icons/crossref.png) . They were designed with concave

regions for the epoxy joints and were extruded to an accuracy of

. They were designed with concave

regions for the epoxy joints and were extruded to an accuracy of  0.05 mm. Tilting table tops were used to lift the RCPs into the

vertical orientation to avoid flexing the epoxy joints. After

assembly, the RCPs were always moved in the vertical orientation or

supported by a rigid flat surface. The barrel RPCs are rectangular in

shape and vary in size 2.2 x 1.5 m

0.05 mm. Tilting table tops were used to lift the RCPs into the

vertical orientation to avoid flexing the epoxy joints. After

assembly, the RCPs were always moved in the vertical orientation or

supported by a rigid flat surface. The barrel RPCs are rectangular in

shape and vary in size 2.2 x 1.5 m to 2.2 x 2.7 m

to 2.2 x 2.7 m .

.

Figure:

Schematic diagram of the internal spacer arrangement for barrel RPC.

|

Figure:

Cross section of the internal spacer and edge in KLM.

|

To distribute the high voltage on the glass, the outer surface was

coated with Koh-i-noor 3080F india ink. The ink was mixed 30 % black

and 70 % white by weight to achieve a surface resistivity of -

/square. This resistivity is chosen so that this

surface does not shield the discharge signal from the external pickup

pads but is small compared to the resistivity of the glass to provide

a uniform potential across the entire surface.

/square. This resistivity is chosen so that this

surface does not shield the discharge signal from the external pickup

pads but is small compared to the resistivity of the glass to provide

a uniform potential across the entire surface.

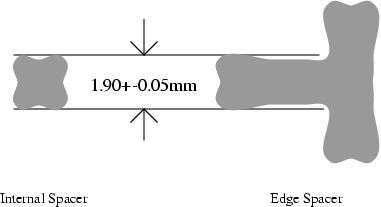

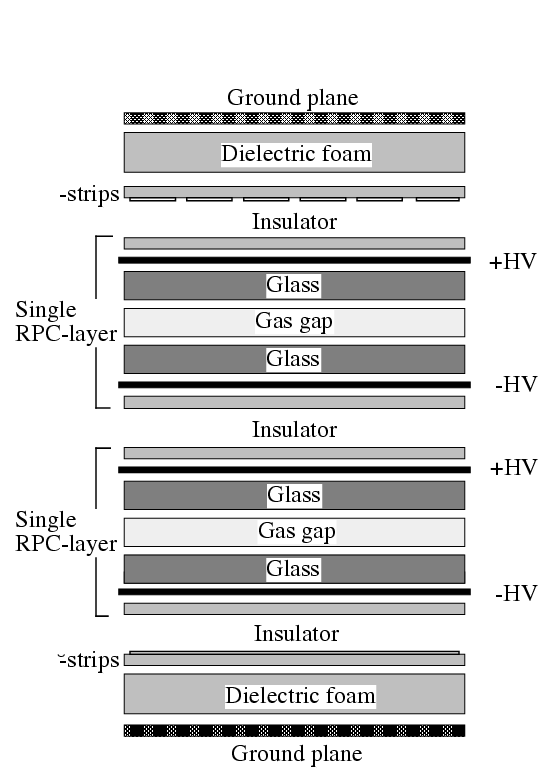

Figure ![[*]](./icons/crossref.png) shows the cross section of a

super-layer, in which two RPCs are sandwiched between the orthogonal

shows the cross section of a

super-layer, in which two RPCs are sandwiched between the orthogonal

and

and  pickup-strips with the ground planes for signal

reference and proper impedance. This unit structure of two RPCs and

two readout-planes is enclosed in an aluminum box and is less than 3.7

cm thick. Each RPC is electrically insulated with a double layer of

0.125 mm thick mylar. Signals from both RPCs are picked up by copper

strips above and below the pair of RPCs, providing a three-dimensional

space point for particle tracking. Multiple scattering of particles as

they travel through the iron is typically a few centimeters. This

sets the scale for the desired spatial resolution of KLM. The pickup

strips in the barrel vary in width from layer to layer but are

approximately 50 mm wide with lengths from 1.5 to 2.7 m. The geometry

of the pickup strips was chosen so that the pickup strip behaves as a

transmission line with a characteristic impedance of

pickup-strips with the ground planes for signal

reference and proper impedance. This unit structure of two RPCs and

two readout-planes is enclosed in an aluminum box and is less than 3.7

cm thick. Each RPC is electrically insulated with a double layer of

0.125 mm thick mylar. Signals from both RPCs are picked up by copper

strips above and below the pair of RPCs, providing a three-dimensional

space point for particle tracking. Multiple scattering of particles as

they travel through the iron is typically a few centimeters. This

sets the scale for the desired spatial resolution of KLM. The pickup

strips in the barrel vary in width from layer to layer but are

approximately 50 mm wide with lengths from 1.5 to 2.7 m. The geometry

of the pickup strips was chosen so that the pickup strip behaves as a

transmission line with a characteristic impedance of  50

50

to minimize signal reflections at the junction with the

twisted-pair readout cable. The barrel modules have a 100

to minimize signal reflections at the junction with the

twisted-pair readout cable. The barrel modules have a 100  resistor connecting the pickup strip to ground at the cable end of the

pickup strip to create an effective impedance of 50

resistor connecting the pickup strip to ground at the cable end of the

pickup strip to create an effective impedance of 50  at that

point. This reduces the size of the signal which reaches the readout

boards for the barrel modules by a factor of two.

at that

point. This reduces the size of the signal which reaches the readout

boards for the barrel modules by a factor of two.

Figure:

Cross section of a KLM super-layer.

|

The double-gap design provides redundancy and results in high

super-layer efficiency of 98 %, despite the relatively low

single-layer RPC efficiency of 90 % to 95 %. In particular, the

effects of dead regions near the spacers are minimized by offsetting

their locations for the two RPCs that comprise a super-layer. To

provide overall operational redundancy, care is taken to supply gas

and HV independently for each RPC layer so that the super-layer can

continue to operate even if a problem develops with one RPC.

Each barrel module has two rectangular RPCs with 48  pickup strips

perpendicular to the beam direction. The smaller 7 super-layers closest

to the interaction point have 36

pickup strips

perpendicular to the beam direction. The smaller 7 super-layers closest

to the interaction point have 36  strips and the outer 8

super-layers have 48

strips and the outer 8

super-layers have 48  strips orthogonal to the

strips orthogonal to the  strips. The

backward region of the upper octant has modules that are 63 cm shorter

than the modules in the other octants in order to accommodate plumbing

for the cooling of the superconducting solenoid. This chimney region

can be seen in

Fig.

strips. The

backward region of the upper octant has modules that are 63 cm shorter

than the modules in the other octants in order to accommodate plumbing

for the cooling of the superconducting solenoid. This chimney region

can be seen in

Fig. ![[*]](./icons/crossref.png) . This amounts to less than 2 % of the solid

angle of the barrel coverage and has a minimal effect on the

acceptance since it is in the backward hemisphere.

. This amounts to less than 2 % of the solid

angle of the barrel coverage and has a minimal effect on the

acceptance since it is in the backward hemisphere.

The glass RPCs are relatively robust except for overpressure

situations which can push the two sheets of glass apart, breaking the

glass-spacer epoxy joint. To avoid this hazard, the gas volume was

not sealed during shipping. Relief bubblers protect the RPCs during

operation. The RPCs were checked for gas leaks prior to installation.

The sensitivity of our measurement was about 0.05 cc/min and this was

the leak rate limit we set for all installed RPCs.

Next: End-cap modules

Up: Design and Construction

Previous: Glass Resistive Plate Counters

Contents

Samo Stanic

2001-06-02