Next: Readout Electronics

Up: Design and Construction

Previous: High voltage system

Contents

We have investigated gas mixtures in search of an environmentally

friendly and non-combustible mixture that provides high detection

efficiency and stable RPC operation [76]. We compared

16 different mixtures with butane concentrations of 4, 8, 12, and 25

% and argon concentrations of 20, 25, 30, and 35 % with the balance

of the gas being HFC-134a. The RPC performance in terms of efficiency,

dark current, singles rate, and timing resolution was compared at an

operating point 200 V/mm above the knee of the efficiency plateau

curve. The butane reduces the presence of after-pulses by absorbing

photons from the initial discharge. The non-flammable limit for the

butane is about 12 % at the mixing ratio of 1:1 for the argon and

HFC-134a. We found very little difference between flammable and

non-flammable mixtures and have chosen a non-combustible mixture of 62

% HFC-134a, 30 % argon, and 8 % butane-silver.

Table ![[*]](./icons/crossref.png) lists some basic physical parameters of these

gases. Butane-silver is a mixture of approximately 70 % n-butane and

30 % iso-butane. The cost of butane-silver is one tenth of the cost

of 99.5 % pure iso-butane.

lists some basic physical parameters of these

gases. Butane-silver is a mixture of approximately 70 % n-butane and

30 % iso-butane. The cost of butane-silver is one tenth of the cost

of 99.5 % pure iso-butane.

Table:

Physical parameters of the gases used in KLM.

| Gas |

Symbol |

Mol. weight |

Density (g/ ) ) |

| Argon |

Ar |

39.95 |

1.784 (0  C, 1atm) C, 1atm) |

| Butane-silver |

C H H |

58.12 |

2.6 (0  C, 1atm) C, 1atm) |

| HFC-134a |

CH FCF FCF |

102.0 |

4.5 |

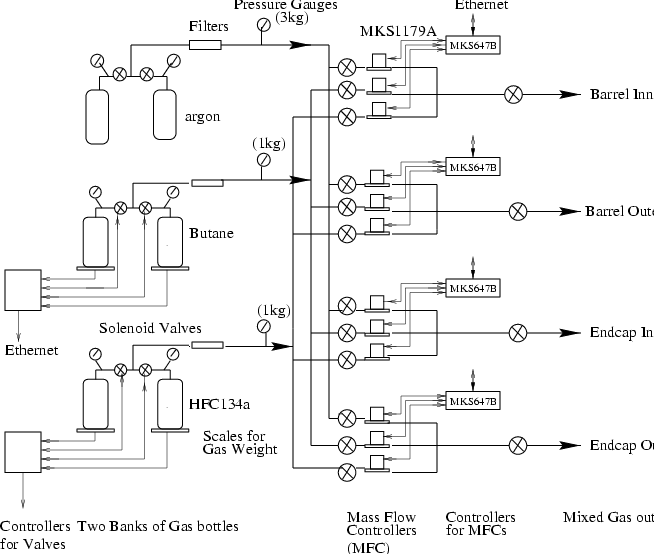

Two separate banks of bottles are arranged for each type of gas. When

one side becomes empty, the supply line automatically switches to the

other. Tank quantities are measured by weight for butane and HFC-134a

and by pressure for argon. A diagram of the mixing system is shown in

Fig. ![[*]](./icons/crossref.png) . The three gases are sent to MKS model

1179A mass flow controllers for mixing in the appropriate ratios.

Four gas mixing systems are used separately for the inner RPCs in the

barrel super-layers, the barrel outer RPCs, the end-cap inner RPCs, and

the end-cap outer RPCs. The flow rates from the mass flow controllers

are monitored via a network connection and the high voltage is

automatically lowered if a deviation from the desired flow rate is

detected. During normal operation, we flow a total of 4.5

. The three gases are sent to MKS model

1179A mass flow controllers for mixing in the appropriate ratios.

Four gas mixing systems are used separately for the inner RPCs in the

barrel super-layers, the barrel outer RPCs, the end-cap inner RPCs, and

the end-cap outer RPCs. The flow rates from the mass flow controllers

are monitored via a network connection and the high voltage is

automatically lowered if a deviation from the desired flow rate is

detected. During normal operation, we flow a total of 4.5  /min,

which corresponds to approximately one volume change per day.

/min,

which corresponds to approximately one volume change per day.

Figure:

KLM gas mixing system.

|

The gas distribution system is designed to provide an independent gas

supply to each RPC in a super-layer. Therefore, if one supply line

fails for any reason, the other RPC in the same super-layer will still

be operational. To ensure uniform distribution of the flow without

the need for tedious adjustments, a "flow resistor" was inserted in

series upstream of each RPC. These devices are 10 cm-long

stainless-steel tubes with an inner diameter of 254  m. The flow

impedance of the tubes is about ten times larger than that of an RPC

layer. Thus the flow rate is determined by the flow resistor (uniform

to about 15 %) and almost independent of variations in the flow

resistance of individual RPCs.

m. The flow

impedance of the tubes is about ten times larger than that of an RPC

layer. Thus the flow rate is determined by the flow resistor (uniform

to about 15 %) and almost independent of variations in the flow

resistance of individual RPCs.

The exhaust system has an active control of the exhaust pressure and

relief bubblers at various points in the system to prevent any

overpressure situations. Tests indicated that epoxy joints between

the glass plates and the internal spacers begin to detach when a

barrel RPC is pressurized above 50 mmAq. For safety reasons, the

exhaust gas is dumped outside the experimental hall through a 20 m

vertical exhaust line. Due to the large density of the mixed gas a

suction pump system is used.

Next: Readout Electronics

Up: Design and Construction

Previous: High voltage system

Contents

Samo Stanic

2001-06-02