Next: Readout electronics

Up: Design and Construction of

Previous: CsI() crystal

Contents

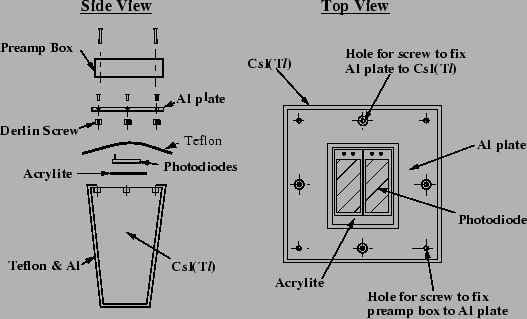

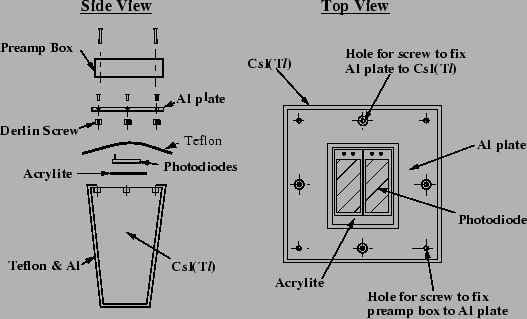

Each crystal is wrapped in a diffuse reflector sheet for the best

collection of scintillation light at the end of the crystal. After

testing several candidates, we have chosen a single layer of 200

m thick Goretex teflon as the wrapping material because it gives

a good light output, is easy to handle, and is expected to be stable

against aging. The mechanical assembly of a single CsI(

m thick Goretex teflon as the wrapping material because it gives

a good light output, is easy to handle, and is expected to be stable

against aging. The mechanical assembly of a single CsI( ) counter

is shown in

Fig.

) counter

is shown in

Fig. ![[*]](./icons/crossref.png) . All sides of the crystal, except for the

end face for light readout, are covered by a single layer of 200

. All sides of the crystal, except for the

end face for light readout, are covered by a single layer of 200

m thick porous teflon. It is then covered by a laminated sheet of

25

m thick porous teflon. It is then covered by a laminated sheet of

25  m thick aluminum and 25

m thick aluminum and 25  m thick mylar for light and

electrical shielding. An aluminum-shielded preamplifier box is

attached on the aluminum base plate with screws.

m thick mylar for light and

electrical shielding. An aluminum-shielded preamplifier box is

attached on the aluminum base plate with screws.

Figure:

Mechanical assembly of the ECL counter.

|

Two photodiodes, each having an active area of 10 mm  20 mm,

are glued at the center of crystal end surface via acrylite plate of 1

mm in thickness. The acrylite plate is used because direct glue joints

between the photodiode and the CsI were found to fail after

temperature cycling, probably due to the different thermal expansion

coefficients of silicon and CsI. ECCOBAND 24 glue from Grace Japan

Co. is used.

20 mm,

are glued at the center of crystal end surface via acrylite plate of 1

mm in thickness. The acrylite plate is used because direct glue joints

between the photodiode and the CsI were found to fail after

temperature cycling, probably due to the different thermal expansion

coefficients of silicon and CsI. ECCOBAND 24 glue from Grace Japan

Co. is used.

The barrel crystals were installed in a honeycomb-like structure

formed by 0.5 mm-thick aluminum septum walls stretched between the

inner and outer cylinders. The outer cylinder, the two end rings, and

the reinforcing bars are made of stainless steel and form a rigid

structure that supports the weight of the crystals. The inner

cylinder is made of 1.6 mm-thick aluminum to minimize the inactive

material in front of the calorimeter. Except for the barrel end,

eight crystals, four rows in  and two columns in

and two columns in  , were

inserted in each cell and fixed to the reinforcing bars through a

fixing jig at the back. In each cell at the barrel end, ten crystals,

five rows in

, were

inserted in each cell and fixed to the reinforcing bars through a

fixing jig at the back. In each cell at the barrel end, ten crystals,

five rows in  and two columns in

and two columns in  , were inserted. The

whole barrel structure was installed in a thick stainless steel

cylinder supported from the magnet. Finite element calculations

indicate that the whole barrel structure would sag

, were inserted. The

whole barrel structure was installed in a thick stainless steel

cylinder supported from the magnet. Finite element calculations

indicate that the whole barrel structure would sag  200

200  m in

the final assembly that is considered to be safe for the contained

crystals. The overall support structure is made gas tight and flushed

with dry air to provide a low-humidity (5 %) environment for the

CsI(

m in

the final assembly that is considered to be safe for the contained

crystals. The overall support structure is made gas tight and flushed

with dry air to provide a low-humidity (5 %) environment for the

CsI( ) crystals. The preamplifier heat, a total of 3 kW, is removed

by a liquid cooling system. An operating temperature of lower than

30

) crystals. The preamplifier heat, a total of 3 kW, is removed

by a liquid cooling system. An operating temperature of lower than

30 C with

C with  C stability is required for the stable operation

of the electronics.

C stability is required for the stable operation

of the electronics.

The end-cap support structure is similar to that of the barrel. Here

the crystal weight is transmitted via a front plate, thin septa, a

side wall, inner/outer walls to thick back-reinforced bars that are

supported from blocks mounted on a support cylinder. The end-cap

calorimeter can be slided out using an additional end-cap mover with

rails when access to the inner detectors is necessary.

Next: Readout electronics

Up: Design and Construction of

Previous: CsI() crystal

Contents

Samo Stanic

2001-06-02